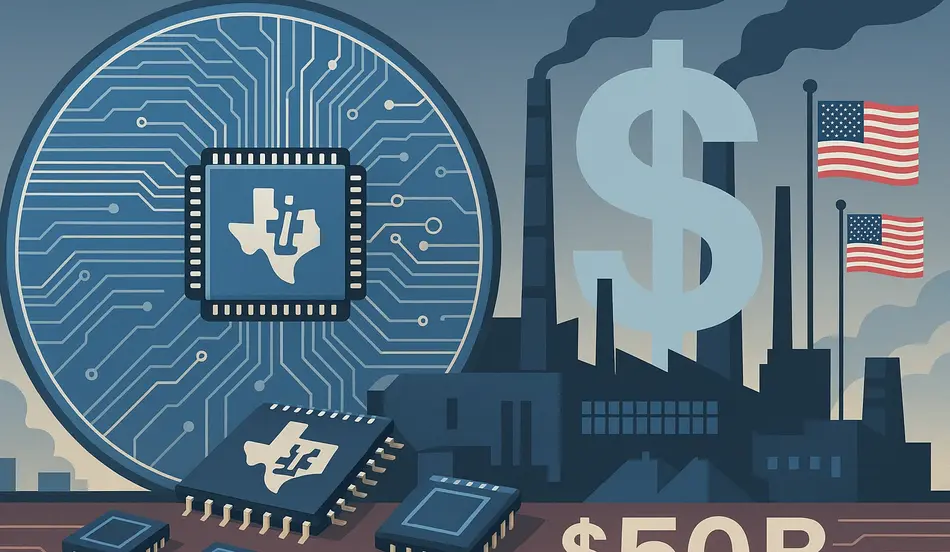

The $60 Billion Gamble on U.S. Chipmaking is now taking shape in North Texas. Rising out of former ranch land are two massive new buildings. One already operates as a clean room, while the other stands as a shell waiting to be outfitted with high-tech equipment. These buildings represent the start of Texas Instruments’ $60 billion investment into seven new semiconductor factories—one of the most ambitious U.S. chipmaking projects in history.

60 Billion Gamble on U.S. Chipmaking

Reflects a broader push to bring semiconductor manufacturing back to American soil, reduce reliance on Asia, and secure national supply chains for critical technologies.

The site in Sherman, Texas is central to this plan. TI will build four factories here, another outside Dallas, and two more in Lehi, Utah. Once complete, the company expects to produce five times more chips than it does today. That means hundreds of millions of chips each day, made in America.

Why This Matters Now

The U.S. has been heavily dependent on foreign chip suppliers for decades, especially in Asia. But with growing political tensions and new 100% tariffs on chips made overseas, companies like Apple are committing to rebuild supply chains inside the United States. Apple recently pledged to source foundational chips for iPhones and other devices from TI’s new fabs.

For Sherman, the project is transformational. The whole campus will cover an area larger than 70 football fields—the size of two Empire State Buildings laid side by side.

The Kind of Chips TI Makes

TI isn’t building the ultra-advanced chips you hear about from TSMC or Samsung. Instead, its focus is on analog and embedded chips. These are small, inexpensive, but essential parts found in almost everything electronic.

- Analog chips handle signals from the real world: sound, light, pressure, and voltage.

- Embedded chips act like the tiny “brains” inside appliances, cars, and devices—telling brakes when to engage, toasters when to pop, or dishwashers when to end a cycle.

While one Nvidia GPU might sell for $35,000, TI chips can cost as little as 40 cents. Yet, without these “support” chips, modern electronics—including AI data centers—couldn’t function.

A Cost Advantage: 300mm Wafers

One of TI’s big innovations is using 300mm silicon wafers instead of the older 200mm size. The bigger wafers produce more chips at nearly the same cost, giving TI a 2.3× efficiency advantage.

This strategy started back in 2009, when TI turned an old memory fab into the world’s first 300mm fab for analog chips. That move gave TI a lasting cost edge and shaped its expansion strategy today.

Tariffs and Global Competition

The timing of TI’s buildout isn’t just about growth. It’s also about resilience. During the 2020 chip shortage, automakers and electronics companies were furious when even cheap parts were unavailable. TI’s response was simple: build enough factories so that shortage never happens again.

New tariffs are another factor. Analysts say TI could actually benefit from tariffs, since rivals who rely on foundries in Taiwan or China will face higher costs. Still, about 60% of TI’s sales come from outside the U.S., with 20% from China, leaving the company exposed to global politics.

Hire Talent to Compete Globally

Post your job on WhatJobs and connect with supply chain experts, semiconductor engineers, and trade specialists who can help your business thrive amid tariffs and global competition.

Post a Job Now →Funding and Incentives

TI is getting strong government backing.

- From Washington, it received $1.6 billion in CHIPS Act funding and qualifies for a 35% tax credit if it breaks ground before 2026.

- Texas has its own $1.4 billion CHIPS Act, plus local incentives in Sherman such as tax breaks and water discounts.

Mayor Shawn Taemann, whose grandfather once worked with TI engineer Jack Kilby (inventor of the integrated circuit), says keeping TI in Sherman is about independence: “Having these chips made here means more security for the U.S. and more stability for TI.”

Water, Power, and Workforce

Chipmaking is extremely resource-heavy. The new fabs will need 1,700 gallons of water per minute, though TI says it will recycle up to 80% of it. Sherman’s Lake Texoma gives the city a rare advantage in water rights.

Electricity is another challenge. Texas’ independent grid has failed before, most notably during the 2021 winter storm. TI says its Sherman site is backed by multiple transmission lines, diesel generators, and renewable energy contracts to guarantee stability.

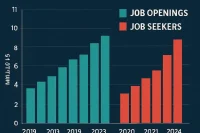

TI also faces a shortage of skilled engineers. The company is partnering with universities, the military, and workforce programs to recruit the next generation of chip talent. In total, the seven fabs are expected to create around 60,000 U.S. jobs.

The Long-Term Bet

TI’s chips don’t make headlines like Nvidia’s or Apple’s. But they are the hidden backbone of modern electronics—powering cars, factories, phones, and even the servers behind AI. By investing so heavily in U.S. manufacturing, TI hopes to secure its leadership in analog and embedded chips for decades.

Executives admit the risk: What if demand doesn’t grow fast enough? But history shows that each wave of new technology—from smartphones to electric cars to AI—requires more chips. And TI wants to be ready.

FAQs

Q1: Why Sherman, Texas, instead of overseas?

Sherman offers access to Lake Texoma water rights, a local power plant, and proximity to GlobalWafers, which supplies raw silicon. Local and state incentives also helped tip the balance.

Q2: How do TI’s chips connect to AI?

They aren’t GPUs but are critical for power management and signal processing in data centers. For example, TI is partnering with Nvidia to make chips that improve efficiency in energy-hungry AI systems.

Q3: When will production start?

The first factory (SM1) is now in the qualification stage and should reach full production by the end of the year. Additional fabs will roll out over time, depending on market demand.

Q4: Could tariffs hurt TI?

Actually, tariffs could help TI. Since it makes more chips in the U.S. than many competitors, its products may become relatively cheaper compared to chips made in Taiwan or China. Still, its large sales in China mean trade tensions remain a risk.