America reindustrialization isn’t happening at least not in the way Washington promised. While there’s rare bipartisan agreement on the need to “bring manufacturing back,” the outcomes so far don’t match the rhetoric. Tariffs, subsidies, and reshoring talk have created headlines, but the data paints a different picture.

This article breaks down why reindustrialization became the political consensus, what the numbers actually say, and the structural reasons the strategy is stalling—plus what might work instead.

Why Both Parties Want Reindustrialization

The political case

- Nostalgia for “good jobs”: Manufacturing was ~25% of U.S. jobs in the 1960s; it’s ~8% today.

- National security: China now produces ~35% of global manufacturing output—more than the next 10 countries combined.

- Supply chain resilience: COVID exposed fragility in pharma, semiconductors, and energy hardware.

The economic logic

- Productivity gains mean fewer manufacturing workers can make more output.

- Globalization shifted production to lower-cost regions while the U.S. specialized in higher-margin services (tech, finance, IP).

Two Strategies, One Goal — Different Tools

Biden-era approach: Subsidize the “new industrial base”

- Inflation Reduction Act + CHIPS Act: Big incentives for EVs, batteries, renewables, and semiconductors—if activity happens on U.S. soil.

- Goal: Build future-facing capacity and cut dependency in strategic sectors.

Trump-era approach: Protect with tariffs; pressure trade partners

- Broad tariffs designed to make imports pricier and domestics more attractive.

- New trade deals that require foreign investment into U.S. assets and plants.

Shaping America’s Next Workforce

Whether through subsidies or tariffs, U.S. policy is reshaping where and how industries grow. Employers can take advantage of this shift by hiring talent ready to build the future of EVs, renewables, semiconductors, and more. Post your job on WhatJobs today and connect with professionals prepared to power America’s next industrial era.

Post a Job Free for 30 Days →What The Data Says (So Far)

Manufacturing activity

- ISM Manufacturing PMI has been contracting in multiple recent reads—seven straight monthly declines at one point.

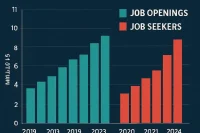

- Manufacturing employment fell by ~42,000 jobs between April and August in the cited window; layoffs rose with ~25% of firms cutting.

Investment headlines vs. reality

- Yes, there’s a capex boom—but it’s overwhelmingly AI/data center–driven.

- Many AI-related imports are tariff-exempt; benefits don’t filter broadly into physical manufacturing.

Trade deficit

- Headline narrowing largely explained by timing quirks in pharmaceuticals and gold flows ahead of tariff changes.

- Adjusted for those swings, the deficit remains near historic levels—undermining the “tariffs fix deindustrialization” thesis.

Strengthen the Workforce Amid Uncertainty

Manufacturing jobs face ongoing pressure despite investment headlines. Employers can play a vital role in stabilizing the economy by creating opportunities for skilled workers ready to adapt. Post your job on WhatJobs today and connect with candidates eager to build resilience in a shifting labor market.

Post a Job Free for 30 Days →Why Reindustrialization Isn’t Materializing

1) Input tariffs raise domestic costs

Tariffs don’t just hit finished goods—they hit inputs. Modern manufacturing relies on complex global supply chains; pricier inputs make U.S.-made goods less competitive, even at home.

2) AI is crowding out capital elsewhere

Massive AI/data center investment can bid up labor, land, and borrowing costs, making it harder for traditional manufacturers to finance and scale—similar to the telecom buildout crowd-out effect in the late 1990s.

3) Labor supply constraints (and policy contradictions)

Rebuilding industries requires specialized workers—often fastest sourced via targeted immigration from countries already strong in those sectors. Hyper-restrictive immigration makes timely scaling harder. The recent ICE detentions of South Korean technicians at a Georgia auto plant highlight the tension; rules were later relaxed because the projects needed those workers.

4) Macro arithmetic fights the policy story

Policies that invite large-scale foreign investment (a political win) tend to strengthen the dollar—worsening the trade balance by making U.S. exports pricier and imports cheaper. You can’t have huge capital inflows without trade-offs.

5) You’re fighting a century-long trend

U.S. manufacturing employment peaked in the 1920s (as a share of total jobs) and has trended down for 100 years due to technology and composition effects. Reversing that mechanically is profoundly hard.

What Might Actually Work

Target the “strategic stack,” not just the final product

- Incentivize upstream and midstream capacity (chemicals, machine tools, precision components), not just final assembly.

- Make input tariffs smarter (or temporary) to avoid kneecapping domestic producers.

Solve the workforce bottleneck

- Fast-track visas for critical trades and process engineers tied to approved projects.

- Scale modern apprenticeships; fund community colleges to deliver industry-aligned credentials in 6–18 months, not 4-year cycles.

De-risk capex for real manufacturers (beyond AI)

- Expand production tax credits to cover core industrial equipment and retrofits, not only green end-products.

- Provide patient, performance-linked financing (public-private) for multi-year ramp schedules.

Build export competitiveness, not just import friction

- Support export consortia for midsize firms (shared sales, service, and certification in target markets).

- Prioritize logistics: ports, rail intermodal, and permitting reform to shorten lead times.

Measure what matters

- Publish a “True Industrial Dashboard” that tracks upstream capacity, domestic content share, time-to-permit, and export penetration—so success isn’t judged by ribbon cuttings alone.

The Bottom Line

America’s reindustrialization isn’t happening—yet. The current toolkit (broad tariffs + splashy subsidies) produces headlines, not durable competitiveness. The path forward is slower, more technical, and more disciplined: fix inputs, unblock talent, target the stack, and raise export fitness.

If the U.S. does that, the next upcycle could be real—not just rhetorical.

Frequently Asked Questions

What does “America’s reindustrialization isn’t happening” really mean?

America’s reindustrialization isn’t happening at scale yet: PMI readings are weak, manufacturing jobs are down, and investment is skewed toward AI/data centers rather than broad-based factory capacity.

Do tariffs help if America’s reindustrialization isn’t happening?

Tariffs can redirect demand at the margin, but because inputs are global, they often raise costs for U.S. producers—one reason America’s reindustrialization isn’t happening as planned.

Why is AI relevant if America’s reindustrialization isn’t happening?

Capital is finite. AI/data center spending can crowd out financing and talent from traditional factories—another reason America’s reindustrialization isn’t happening evenly.

Can immigration policy fix why America’s reindustrialization isn’t happening?

Targeted, pro-industry visas help. Without experienced technicians and process engineers, timelines slip—one reason America’s reindustrialization isn’t happening on schedule.

A Live Example: A Midwestern EV Supplier’s Dilemma

A Tier‑2 EV components firm in Ohio won a major contract in 2023. The plan assumed:

- Duty-free access to specific precision inputs

- 18-month lead time for skilled technicians

- 6% borrowing costs

What happened instead:

- Input tariffs raised landed costs by ~9%, blowing up margins

- Visa delays pushed commissioning back 7 months

- Rates rose, adding ~$2.4M to lifetime financing costs

Result: The firm deferred its Phase 2 expansion and shifted part of the order to a partner in Mexico. Policy friction—not demand—stalled a textbook reindustrialization opportunity.