The warehouse labor crisis continues to disrupt the U.S. supply chain, even as post-pandemic e-commerce growth slows. Despite reduced consumer demand, logistics and transportation sectors remain under immense strain. Companies ranging from freight haulers to last-mile delivery services are still struggling to fill critical job roles across warehouses and logistics hubs.

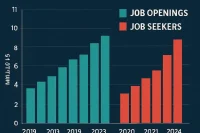

As of mid-2025, the warehouse labor crisis has intensified. Warehouses are adopting AI-driven automation, delivery fleets are going electric, and freight carriers are increasing wages. Still, jobs remain unfilled. The gap between labor supply and demand continues to widen across long-haul trucking, last-mile delivery, and warehouse logistics putting further pressure on an already fragile supply chain.

The Post-Boom Plateau in E-Commerce

From 2020 to 2022, the pandemic-fueled surge in e-commerce drove exponential growth in online sales, prompting an equally explosive expansion of logistics operations. However, by 2024 and into 2025, online sales growth has slowed to more stable year-over-year increases of 3% to 5%. Amazon, Walmart, and Shopify reported plateauing consumer growth, even as return-to-store shopping rebounded.

Despite this moderation, consumers’ expectations for fast, cheap, and reliable delivery remain unchanged. One-day or even same-day shipping has become standard in major cities. This demand for speed—rather than volume alone—has locked the logistics industry into a cycle of overcapacity and understaffing.

Trucking in Crisis: Long-Haul Labor Deficit

The Numbers Behind the Shortage

The American Trucking Associations (ATA) estimates a current shortage of 64,000 truck drivers, down slightly from the peak in 2022 but still well above the ten-year average. Projections suggest the gap could exceed 85,000 drivers by 2027 if replacement rates for retirees don’t improve.

This deficit is especially pronounced in long-haul freight. Aging baby boomers, who make up a large portion of the current workforce, are retiring. Meanwhile, lifestyle drawbacks—weeks away from home, sedentary work, and strict scheduling—make it difficult to attract younger candidates.

Recruitment Struggles and Wage Pressures

Carriers have responded with aggressive incentives. In 2025, average entry-level pay for truckers now exceeds $65,000, with sign-on bonuses reaching $15,000 in some regions. Yet turnover remains high, often exceeding 90% annually at major freight companies.

Some states, like Texas and Georgia, have begun subsidizing CDL (commercial driver’s license) programs and offering incentives for veterans to enter the field. Despite this, hiring pipelines remain sluggish.

Warehousing Woes: High-Tech Facilities, Low-Interest Labor

The Evolution of Distribution Centers

Warehouses have become smarter and larger. Automation—from robotic arms to guided vehicles—is reshaping distribution centers nationwide. DHL and UPS, for example, now operate dozens of semi-automated hubs equipped with AI for inventory management and real-time routing.

Yet, these technological advances haven’t resolved the worker shortfall. Warehouse roles still exist for inventory control, machine operators, safety compliance, and loading tasks that machines cannot yet fully replicate.

The Turnover Dilemma

Warehouse jobs are often viewed as low-status, physically demanding, and precarious. The result: an average turnover rate of over 50% annually. Labor experts point out that despite rising hourly wages (averaging $19–$22 per hour in 2025), the nature of the work continues to deter applicants.

Moreover, labor competition from gig economy roles—such as food delivery and rideshare driving—has made it even harder to fill warehouse jobs in urban and suburban areas.

🚛 Explore Warehouse & Logistics Jobs on WhatJobs

Searching for stable, hands-on work in a fast-evolving industry?

Discover in-demand opportunities in warehousing, logistics, transportation, and inventory management — especially as automation reshapes the supply chain.

WhatJobs connects you with employers upgrading to high-tech distribution centers while urgently seeking skilled talent to close the labor gap.

👉 Browse top warehouse and logistics jobs now — and be part of the workforce powering the modern economy.

The Bottleneck of Last-Mile Delivery

Expanding Urban Expectations

Last-mile delivery—the process of getting goods from a warehouse to the customer’s doorstep—is the most labor-intensive and costly segment of the supply chain. It accounts for over 53% of total shipping costs.

Urban congestion, rising fuel costs, and customer expectations of precision timing have created a logistics nightmare for companies like FedEx, Amazon Flex, and DoorDash. Each missed delivery or delayed ETA undermines customer loyalty and brand performance.

Labor Volatility in the Gig Model

Many last-mile services depend on independent contractors who operate under “gig” arrangements. These workers lack traditional employment protections and can easily switch platforms. During peak seasons, shortages are common, with some cities reporting delivery delays of 24 to 72 hours.

Rural areas face the opposite issue: too few deliveries to justify full-time driver deployments, leading to inconsistent service and high costs per package.

Industry Adaptation: Strategies for Stability

Boosting Benefits and Flexibility

To combat labor shortages, companies are overhauling their employment models. Major logistics firms have started offering:

- Tuition assistance for training programs

- Guaranteed weekends off for long-haul truckers

- Expanded health and wellness perks

- Performance bonuses tied to safety and delivery metrics

These strategies aim to professionalize logistics roles and offer more sustainable career paths.

Investing in Human-Tech Integration

Automation is not replacing labor—it’s changing it. Employers now need workers who can operate robotic forklifts, analyze logistics data, or troubleshoot AI systems. This shift requires upskilling programs, partnerships with community colleges, and in-house apprenticeships.

Amazon’s “Career Choice” program, for instance, offers front-line workers free training in logistics tech and systems engineering—helping bridge the gap between traditional labor and smart logistics.

Policy Levers and Infrastructure Support

Immigration and Workforce Supply

Many in the logistics industry argue that legal immigration reform is critical to addressing labor shortages. Temporary work visas for truck drivers and warehouse staff, now limited, could be expanded under new federal proposals. Canada has already adopted similar policies to plug gaps in its logistics sector.

Infrastructure Investment

The U.S. Infrastructure Investment and Jobs Act, passed in 2022, includes billions for highway modernization and port upgrades. These improvements are essential for logistics efficiency but also indirectly impact workforce needs—by improving driver conditions, reducing downtime, and optimizing delivery routes.

Looking Ahead: The Future of Transportation and Delivery Work

While robotics and AI will continue to expand, industry insiders agree that human labor remains indispensable—especially in unpredictable, customer-facing tasks. The logistics labor force of the future will likely be smaller but more skilled, better paid, and technologically integrated.

Success hinges on three pillars:

- Policy Alignment: Immigration, education, and labor laws must evolve with the industry.

- Cultural Perception Shift: Logistics needs a brand makeover to attract the next generation.

- Technology with Training: Automation must be paired with investment in people, not used as a substitute for them.

FAQs

Q: Why is there still a labor shortage if e-commerce growth has slowed?

A: Despite slowing e-commerce, delivery expectations remain high. Companies must maintain fast shipping, which requires significant labor—even with stable order volumes.

Q: Is automation a long-term solution?

A: Partially. Automation reduces reliance on manual labor for routine tasks but increases demand for tech-savvy workers who can manage and maintain complex systems.

Q: Are these shortages leading to higher prices for consumers?

A: Yes. Increased logistics costs—especially in last-mile delivery—are often passed on through shipping fees or built into product pricing.

Q: What roles are in highest demand right now?

A: CDL-certified truck drivers, last-mile couriers, warehouse tech operators, and logistics planners are among the most sought-after in 2025.

Final Word

Labor shortages in transportation, delivery, and distribution are no longer a pandemic-era anomaly—they’re a structural challenge. Even as digital retail settles into a slower growth phase, the human capital crisis in logistics shows few signs of abating.

Addressing this issue requires a multi-pronged strategy: incentivizing workers, modernizing perceptions of logistics careers, integrating human-centric automation, and enacting policy reforms. Without decisive action, America’s supply chains will continue to suffer—not from lack of demand, but from lack of hands to deliver.